Projects

Whether your business is focused on commercial air travel, cargo transport, emergency medical services, military operations, or specialized missions like search and rescue, SME’s comprehensive services can have a big impact on your operational and financial efficiencies.

SME is the right crew to manage your job!

Our senior level project management services provide a customized approach to fit your program individual needs so that your project delivery is on target for your programs budget and timeline. Working with FBO’s (Fixed-Base Operators), MRO’s (Maintenance, Repair, Overhaul), Corporate Flight Departments, Airports and HEM’s (Helicopter Emergency Medical Services) our team has seen many challenges and roadblocks to the base building process. We can navigate these issues for you and postion your program to avoid internal staff frustration, unnecessary expenses, lost time, and will build a base that is designed to fit your end use.

At SME we know that every project has an impact – and our project leaders will make sure that your base project has a positive one. By selecting SME, you are engaging a team that has the specialized knowledge and experience to manage your project from start to finish – a team that you can depend on to handle the full scope of your niche development and construction project, keeping your program’s best interests and particular needs in mind. The result will be a positive impact on your business and community relationships and on your program resources, namely people and capital.

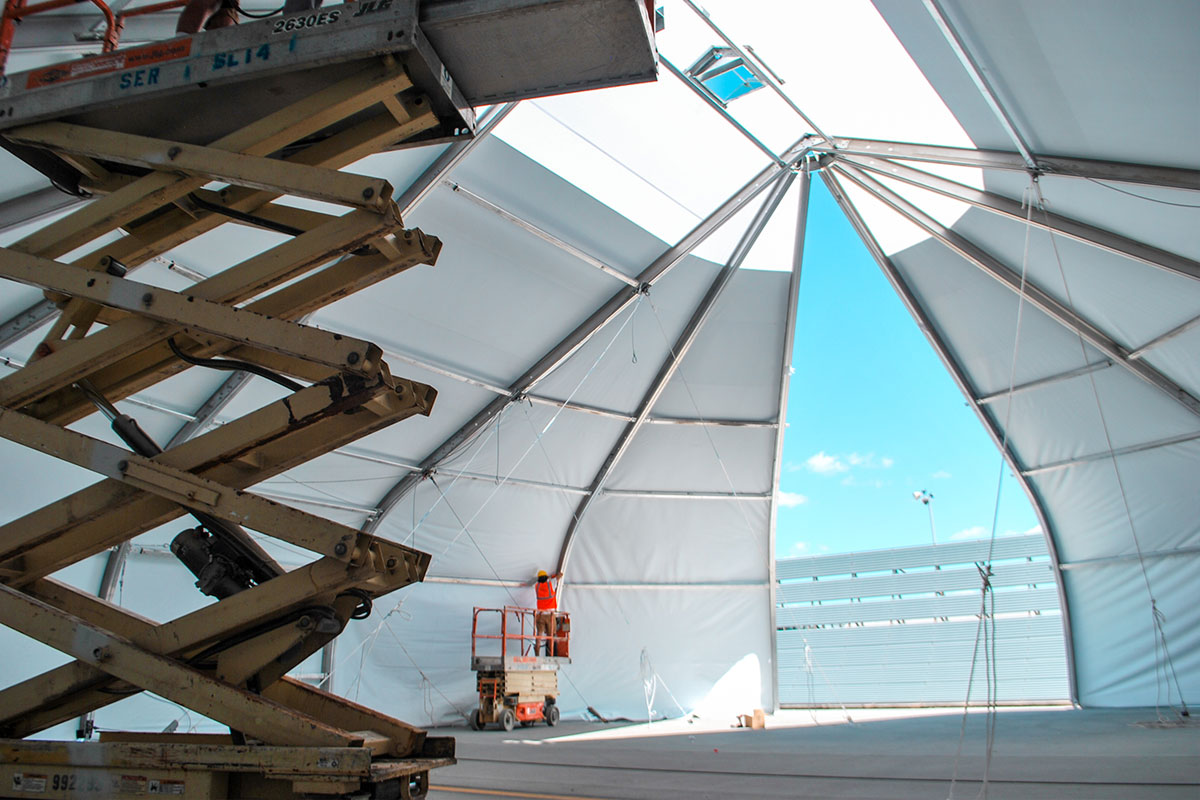

Temporary Base

This temporary base got our client’s program up and generating revenue a full 14 months ahead of schedule and paid for itself in just the first three weeks of operation.

SME Craftsmen

Experienced SME craftsmen ensure project timelines are met and programs are operational on schedule.

Branded

SME handles everything from designing the base to branding the assets.

Solutions

Industry-inspired solutions get programs operational ahead of schedule.

On-site

The SME team will be onsite to ensure a smooth build and handoff.

Case Studies

Your Title Goes Here

Some text here

NEGOTIATIONS SAVED OUR CLIENT MORE THAN $250K

This is a recent example of how inexperienced project planning sent a base building project careening off the tracks – and how SME was able to rescue it.

In expanding their operations to a new hospital location, a flight program decided to manage the project internally. The project quickly became complicated. The hospital volunteered to provide land for a new base. The project team assumed that a crew quarters could be easily purchased from a local modular home dealer and installed on the hospital property.

A number of things went wrong. In planning the project timeline, a local modular home dealer was consulted, and a 30-day timeline was assigned to the task of purchasing and installing the crew quarters on the hospital property. This home was a HUD code building3, and the team didn’t understand the differences in available building codes for homes. When the project started and the engineered home documents were submitted, the building department refused to issue a building construction permit because HUD code buildings were not allowed for commercial occupancy. An initial 4-month delay was incurred on the project to custom build an IRC-Code modular home.

A custom home was designed, and the new IRC Code4 building plans were engineered and delivered to the building department, who rejected them again due to additional non-compliance issues: IBC Code construction for live load and a fire protection system were also required. Now the project was looking at a 5-month delay and an additional $300k in construction costs.

With this serious increase in time, costs, and complexity, the program made the decision to engage the SME team. After an initial meeting with all stakeholders, SME negotiated:

- the code requirements to allow for a residential-code, on-frame modular building

- a reasonable fire protection system requirement

- infrastructure responsibilities with the landowner to transfer burdensome costs away from our client

While the base had in-fact opened late, the client saved more than $250K. Had our team been engaged during the planning phase, this costly and frustrating delay could have been easily avoided, and the base would have opened on time.

SME DUE DILIGENCE PAYS REAL DIVIDENDS

A program was expanding their operations at a local EMS base, which had a 20-year-old helipad that was still in use. From the beginning, the program involved SME experts, who completed a thorough due diligence process and found that even though the helipad was currently in use, a supplemental use permit (SUP) was required in order to move forward with construction. This requirement was completely unconventional given that the EMS base and helipad were already in active community use; however, since an aircraft had not been based at this site, the SUP was required. The zoning SUP request required a public hearing process, which was held quarterly in this particular jurisdiction area. If the SUP requirement had not been identified prior to submitting the building permit application, the package would have been rejected, causing the program to miss the window for the next public hearing. Although seemingly simple, this development project would have suffered a 6-month delay without the proper due diligence.

COST SAVINGS DURING ZONING NEGOTIATIONS

SME was hired to build a crew quarters and helipad at an off-airport site. The town planning and zoning commissioner provided a landscape plan (requirements) which planting a specific number of trees/ square foot of land that was disturbed by our project. The trees were required to be 7-10 ft tall (upon planting). Not only was this an expensive requirement, but it also rendered the helipad inoperable. We had to negotiate with the city to obtain a variance to delete the tree requirement based on the intended use of the land.

AVOIDING UNEXPECTED COSTS

A program was expanding to a new site at an affiliate hospital. To help bring in the needed air medical service, the hospital offered their nursing annex building as a base for the flight crews. The hospital also committed to doing building renovations. Because of this, no base construction tasks were included in the project plan. However, when the hospital submitted the upgrade request to the building department, it was denied. The annex building, built pre-1950’s, was in good condition but lacked any fire suppression or alarm systems, meaning that the crews would not be permitted to sleep in the space – an obvious need. The cost of upfitting the building with the required fire systems was prohibitive, so the program needed to provide its own crew quarters. With proper planning during the due diligence phase, this requirement would have been identified. As it played out, the required crew quarters unexpectedly increased both the project budget (+$250,000) and timeline (+4 months).